APPLICATIONS

Printed electronics opens up a vast field of innovation, with a wide range of applications. Dynamic private and public investment in Europe, combined with significant advances in production techniques and the materials used, point to promising growth for this new industrial sector, particularly in France. These applications are aimed at both high-value-added professional markets and mass markets for the general public.

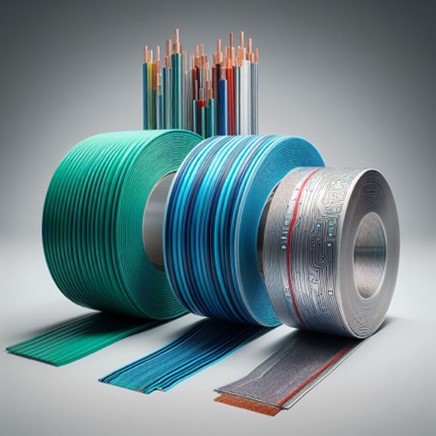

CABLING

Connectivity in environments where weight and space savings are a real issue is tending to move towards printed wiring on flexible substrates, bus-bar style. This is the case in aeronautics (and drones), where every gram saved translates into reduced power consumption or longer flight times. The same trend can be found in the field of electric vehicles, which are very sensitive to the weight savings induced by the presence of batteries.

HEATING

Using conductive and resistive materials with Joule effect, heating modules can be integrated for applications ranging from simple windshield or giant wind turbine blade de-icing, to integration in heated car seats, or in clothing fabrics for severe climatic conditions. The dynamics of the electric vehicle market are also driving applications for heating elements in battery protective cases for improved cold-start performance. We are also seeing ‘digital heating’ applications, where ‘pixel heaters’ are selectively activated to heat specific areas in everyday life;

H&M INTERFACE

Certainly one of the oldest and most popular applications of Printed Electronics is the creation of keypads with very different form factors and sizes, depending on the target application (automotive, white goods, cell phones, etc.). The electronic part is screen-printed and then combined with printed decorations, screen-printed in color in the same environment. Over time, the techniques and materials used have become increasingly sophisticated: from membrane keypads, to capacitive keypads, to self-generating piezoelectrics and force feedback for improved equipment control.

MEDICAL – BIOTECH/MEDTECH – PHARMACEUTICALS

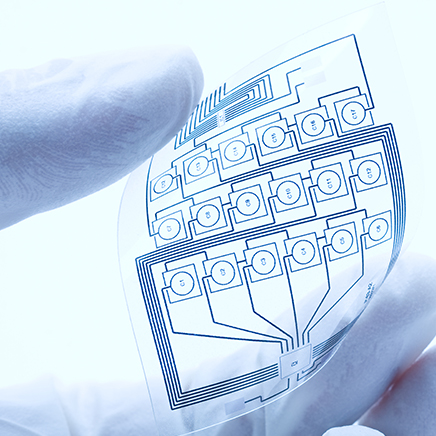

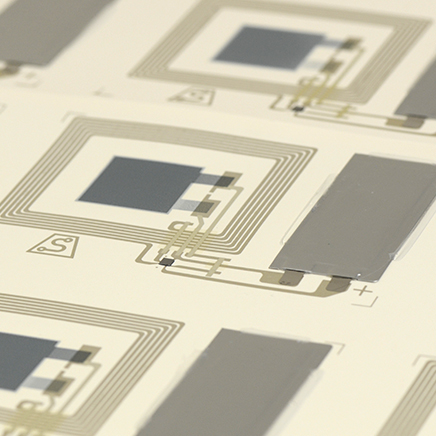

Medical applications are numerous. The first and most important in terms of volume are glucose sensors for controlling blood sugar levels in diabetics. But we can also add intelligent patches for monitoring certain biological parameters (ECG, pH, sweat, skin conductivity), which can be integrated into clothing, T-shirts, gloves and socks. Other emerging applications include smart labels equipped with RFID for security and traceability, which indicate a medicine’s expiration date, or those which indicate whether the cold chain has not been broken during transport, or whether shocks have been recorded. Organic piezo materials, electrochromic color displays and OLEDs are obviously well-suited to these applications.

There are also a growing number of start-ups working on the Brain-Machine interface, using printed wiring devices, since managing size and weight is crucial, or highly innovative approaches integrating antenna arrays directly into the textile of a patient’s garment during an MRI examination, to enhance image quality and reduce motion blur, thus boosting productivity in the imaging department.

AEROSPACE

The aerospace environment is a very interesting playground for printed electronics players, as weight and form factor challenges are crucial. Window de-icing systems in transparent conductive ink, weight-saving printed wiring to distribute multimedia channels to passengers, MetaSurface for radar radomes, strain gauges integrated into the structure, heating elements to secure strategic parts of the aircraft, man-machine interface in the cockpit, etc.

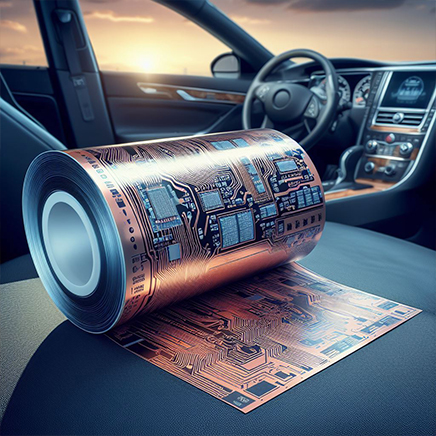

AUTOMOTIVE

Red OLED taillights whose luminosity and lifespan are superior to inorganic LEDs on luxury vehicles, Transparent conductive ink de-icing system for front lights which are inorganic LEDs and therefore non-heating, Heated seat, New Human-Car Interface on the dashboard compatible with automotive standards directly integrated on the dashboard, Heated elements in the battery casing on electric vehicles, replacement of wiring to save precious kilos…

ENERGY

This is obviously a fast-growing field, encouraged by the many private and public investments being made to reduce carbon footprints. From the battery or supercapacitor made using printed electronics technology, to heating systems or echo-acoustic integrity and wear control systems fitted to battery casings, printed wiring harnesses to reduce line losses while saving weight and space, structural control systems (wind turbine blades, hydrogen tanks) to ensure a longer service life for energy generation systems, etc… The fields are very broad and are in the making.

DEFENSE – SECURITY

Whether for the protection of soldiers or police officers, numerous initiatives are underway to better equip our personnel on the ground, in the air and at sea, sponsored for example by France’s Direction Générale de l’Armement (CENTURION project). The “augmented” soldier, with a multi-modal view of the field of operations, continuously connected to his hierarchy for his protection and that of civilians, remains the priority of our armies and police.

Similarly, countermeasure systems, with interception radars becoming increasingly sophisticated, account for a significant proportion of on-board equipment on military aircraft and ships. The best way to integrate them and save weight is to use printed electronics, because of their conformability, thinness, flexible form factors and light weight for equivalent electronic performance.

PACKAGING – LABELS

Packaging is a very rich application area for printed electronics. Anti-counterfeiting and traceability are important issues for clients in the luxury goods industry, for example, while many brands are looking to reduce their carbon footprint and want to adopt more recyclable materials while differentiating themselves from their competitors. Paper/Cellulose electronics is an effective and elegant approach to being more virtuous in single-use cases (green & sustainable electronics), as its recyclability has been repeatedly proven using paper/packaging waste management processes.