KELENN

FROM LAB TO FAB

KELENN Technology matches the requirement from customers with a turnkey solution.

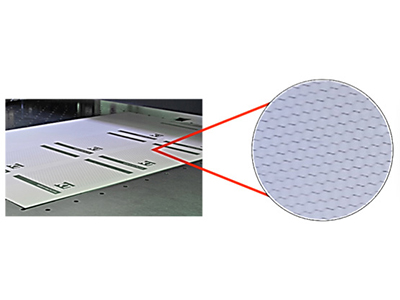

The KSCANtm innovative production platforms from KELENN Technology are cost efficient for manufacturing in low to medium volumes of large area electronic devices.

Thanks to a scalable architecture, customers can start from lab scale, deposition of patterned functional fluids such as conductors, organic semiconductors and dielectrics. Sliced high speed inkjet print head sub systems, high resolution vacuum flat beds, drop watcher and photonic annealing equipment are all in one enclosure for high efficiency 2D and 3D digital deposition of multiple layers of a mix of functional fluids.

For industrial production run, automated feeder, registration, stacker, inspection cameras are integrated into the system. A fully automated process is then available to our customers.

First KSCANtm is available on the market in sheet to sheet configuration.

THINK DIGITAL

Thanks to the Digital Factory concept developed by KELENN Technology, business oriented companies can link their new developments and standard product offering to their customers in real time to win the competition challenge.

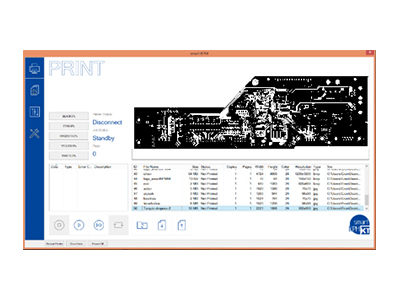

Indeed, KELENN Technology has unified the process of layout design, production, camera inspection, tracking and production management in a unified and customizable process to reduce time to market and cost of operation.

Furthermore, KELENN Technology’s unique KEOS_PEtm reliable Ink jet deposition sliced systems; has many benefits: it runs at high speed and high resolution, it requires very limited amount of raw material such as nano particle of silver ink, it delivers better productivity at single pass yield and it requires lower setup time.

The Digital Factory from KELENN Technology brings further benefits such as: reduced energy requirements, less waste, new innovative product opportunities and new business models.

THINK SMART

Since 10 years, KELENN Technology has been involved into the digital factory concept. Today a number of software tools are being made available to our customers into a foundation environment:

- Smart PMtm: production management

- Smart VDGtm : layout and layer editor, variable data generator, interface with CAD,...

- Smart KPMtm : scripting, operator control, spooling, file management, process automation...

GLOBAL SERVICING

KELENN Technology has developed a proven expertise in installation, training, commissioning, servicing and hot line services to key industrial players worldwide. With subsidiaries in the USA and ASIA, KELENN Technology has the capability to synchronize with different time zones for best efficiency. In a world of competition and innovation, KELENN technology provides all these services and product customization with absolute confidentiality and with a partnership vision.

6 rue Ampère

91430. IGNY

France

Tel : +33 (0)9 75 23 33 54

info@kelenntech.com

Contact

CEO

Didier ROUSSEAU

Didier.rousseau@kelenntech.com

Site internet

https://www.kelenntech.com/