VFP

The applications of VFP functional inks are dedicated to the RFID market, tag fabrication, flexible electronics and the electromagnetic shielding.

An experience of 20 years in the ink formulation

Established in 1994, VFP Ink Technologies is a division of Tripette & Renaud group. . The company is specialized in inks development within an approach of adaptability to the specific customer needs. This expertise is now being implemented for the development of functional inks:

IR-blocking inks are designed for the manufacture of transparent bank cards. They are used for transparent bank cards to detect the presence of the card in ATM machines and other readers processing IR sensors. Themain function of IR Blocking inks is to absorb infrared light.

In order to respond to the printed electronic devices requirements, the products createdby VFP Ink Technologies have been designed in the target of reducing the costs, minimizing environmental impact and simplifying implementation:

- Formulations based on pure silver are made with a low mass fraction.

- Other formulations are proposed starting from conductive particles made of a silver coating and a non-precious metal core; which constitute 80% of particles weight.

- The formulations are free of nanoparticles and solvents classified as toxic, CMR or harmful.

- All printing, drying and annealing steps can be performed in open air.

- The inks do not require the use of expensive post-printing processing methods such asphotonic or laser annealing, only a thermal treatment in an oven has to be carried out.

The VFP products for printed electronics

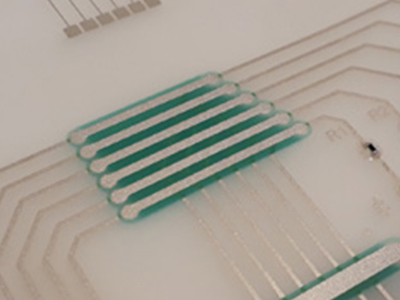

Conductive inks

These products made from silver metal particles are available in two formulations which need a thermal treatment at 150°C for 10 min:

- Silver Electron: Single-component system with a conductivity of 13 mΩ/sq/mil (1 mil =25,4 μm).

- Dual-component system with a conductivity of 40 mΩ/sq/mil. (Once the two components are mixed, working time without degradation of properties is one week).

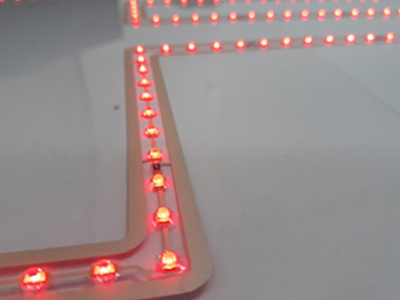

Inks combine magnetism and conductivity

These media are made of silver coated nickel particles in a single-component system and must be annealed at 150 ° C for 30 min.

A focus on innovation

Firmly committed to innovate, VFP Ink Technologies Company is currently involved in various projects in order to develop new functional inks with academic and industrial partners. We also remain open to achieve the development of new active materials ink (conductive, magnetic, piezoelectric, pyroelectric...) for printed electronics applications.

Immeuble le TREMA

163 Quai Aulagnier

CS 40058

92601 ASNIERES SUR SEINE Cedex

Site de production

ZI du Vermeillet

Route de Montpellier

30380 Saint Christol Les Alès

Tél : +33 (0)4 66 60 98 985

Contact

Jeremy Flageul

Sales Director

jflageul@vfp-ink.com

Tél : +33 6 67 63 56 29

Site internet

https://www.vfp-ink-technologies.com/