IN-CORE Systèmes

Lineavision® advanced image processing technology enables to precisely define, characterise and control in real time, either single or multilayer structure of printed electronics products reaching accuracy down to 1μm and to monitor R2R, S2S processes at each manufacturing step.

Lineavision®equipment addresses a wide range of flexible printed electronics applications: substrate & barrier film, printed circuits, thin film batteries, OPV (organic photovoltaics), RFID Antennas, printed transistors, ...

Lineavision®: modular in-line concept optimally suited for:

- 100% high-speed, large or narrow substrate surface inspection

- Process monitoring (printing, coating, laminating, annealing, assembling, ...):

- Defect aspect control

- Registration of structures and layers from multi- print steps

- Geometrical pattern/ feature/ layer measurements (Position & registration, alignment, edge regularity, spacing, ....)

- Real time full traceability solutions and quality control for global data management:

- Inspection at each process steps of interest

- Identification of the origin of the defect

- Consolidation of all processed data & archiving

- Tracing the defective circuits/ modules along the entire production -> defects can be removed or repaired in following process steps

- Post process software tools (classification, statistics, ...)

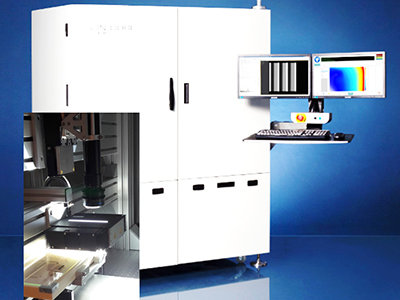

Latest innovation: advanced technology validation device

High-resolution multi-purpose sensors based metrology and characterisation platform ÉlaDesigned to inspect and measure at highest precision on large area, flexible various substrates, Lineavision® characterisation platform, provides non-contact, manual or automated defect detection and location. The system provides advanced metrology capability to analyze single and multilayer structures (GEN1 ->GEN10) for defining and assessing quality and manufacturing process steps.

Multi-purpose device optimally suited for:

- Optical metrology for single and multi-layer product,

- High-accuracy motion in XY directions

- High-resolution measurements and analysis,

- Pattern recognition software,

- PDF comparison & pattern self-learning.

10 rue Ampère

69680 CHASSIEU

Contact

Michel POPOVIC

Michel.popovic@incore-systemes.com

Site internet

https://www.incore-systemes.com/